Defined by the European Commission as a paradigm focused on human-centricity, environmental sustainability, and resilience, Industry 5.0 aims to create smart factories where collaboration between humans and machines not only optimizes production but also improves quality of life while reducing environmental impact.

Known as the fifth industrial revolution, Industry 5.0 is not just an upgrade from Industry 4.0 but an evolution in itself, centered on social well-being and the circular economy.

Table of contents

Differences between Industry 5.0 and Industry 4.0

To fully understand Industry 5.0, we first need to compare it with its predecessor. Industry 4.0 focused primarily on digitalization and automation, driven by technologies such as the Internet of Things (IoT), artificial intelligence (AI), and cyber-physical systems. Its main goal was to increase production efficiency and reduce costs.

In contrast, Industry 5.0 shifts toward a more human-centric approach: here, technology adapts to human needs rather than the other way around. While Industry 4.0 sought to minimize human involvement in favor of productivity, Industry 5.0 enhances human creativity and ingenuity by combining them with collaborative robots (cobots) and AI to create safer and more innovative workplaces.

Another key difference lies in the emphasis on sustainability and resilience. Whereas Industry 4.0 prioritized digital optimization while often overlooking environmental and social concerns, Industry 5.0 actively promotes circular economy practices. It reduces waste and carbon emissions by leveraging recyclable materials and more energy-efficient processes.

According to analysts, these shifts are expected to make Industry 5.0 more resilient in the face of economic downturns, pandemics, and geopolitical changes.

The pillars of Industry 5.0

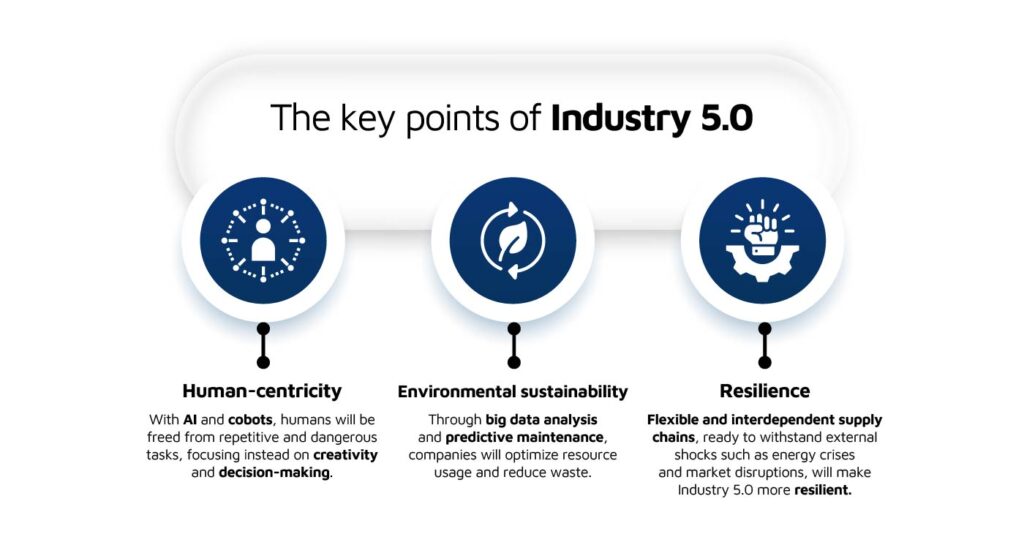

The foundations of Industry 5.0 can be summarized in three main pillars:

1. Human-centricity

The first pillar places humans at the core of production processes. With technologies such as AI and cobots, workers are freed from repetitive and dangerous tasks, allowing them to focus on creativity and decision-making. According to Eurostat data, this not only boosts productivity but also improves workplace safety, with a significant reduction in accidents and physical strain.

2. Environmental sustainability

Environmental sustainability is another key element. Industry 5.0 promotes the use of renewable energy to minimize impact on ecosystems. For example, through big data analysis and predictive maintenance, companies can optimize resource usage and reduce waste.

3. Resilience

Finally, flexible and independent supply chains, capable of withstanding external shocks such as energy crises and market disruptions, make Industry 5.0 more resilient.

Overall, Industry 5.0 does not replace Industry 4.0 but expands it, adding a stronger focus on worker well-being and environmental sustainability.

Real-world examples

Let’s now consider some real-world applications. In manufacturing, smart factories use digital twins—virtual replicas of physical systems—to monitor the status of products and services in real time and predict failures. A notable case is Ferrero, which has implemented digital twin technology to optimize routes, streamline deliveries, and cut costs.

In healthcare, the medtech sector—bringing together companies, research centers, and healthcare organizations—represents a dynamic ecosystem capable of reducing costs and recovery times. Personalized medical devices, such as 3D-printed prosthetics and AI-based predictive diagnostics, improve treatment effectiveness.

In the construction Industry, new smart materials like graphene enable the rapid building of complex structural components. In transportation, autonomous vehicles and AI-driven logistics are optimizing routes and delivery processes.

Bosch Rexroth is a strong example, with platforms such as ctrlX AUTOMATION and 7-axis robots fostering a seamless integration between humans and machines. Similarly, TeamSystem provides software for real-time production monitoring, turning factories into highly automated and efficient environments.

Future outlook

Industry 5.0 is not just a passing trend but an opportunity to redesign the industrial future in a sustainable and inclusive way. With benefits such as increased productivity, reduced workplace risks, and greater global competitiveness, companies that embrace this paradigm will be better equipped to thrive in an increasingly demanding economy.

Shaping the future of the EU together

Are you interested in Industry 5.0 and eager to explore its business opportunities? Don’t hesitate to get in touch! We are looking for partners for European projects because we believe that, together, we can accelerate the transition toward a more human-centric and resilient Industry, contributing to the future of Europe.

The consortia we are building will focus on:

- research and development (R&D) projects in collaborative automation, digital twins, AI, and sustainability;

- resilient, green industrial solutions with strong social impact;

- training initiatives to equip human capital for the future.

Join our network and contact us today! Join us to build hubs of excellence, attract funding, and transform Europe’s industrial landscape with an Industry 5.0 perspective.